Ogo bu ndu AISEN.Usoro njikwa mma kachasị mma nke AISEN na ụkpụrụ ịdị mma ngwaahịa nwere ike inyere ndị ahịa na ụlọ ọrụ nhazi ya aka ịchekwa ego na oge.

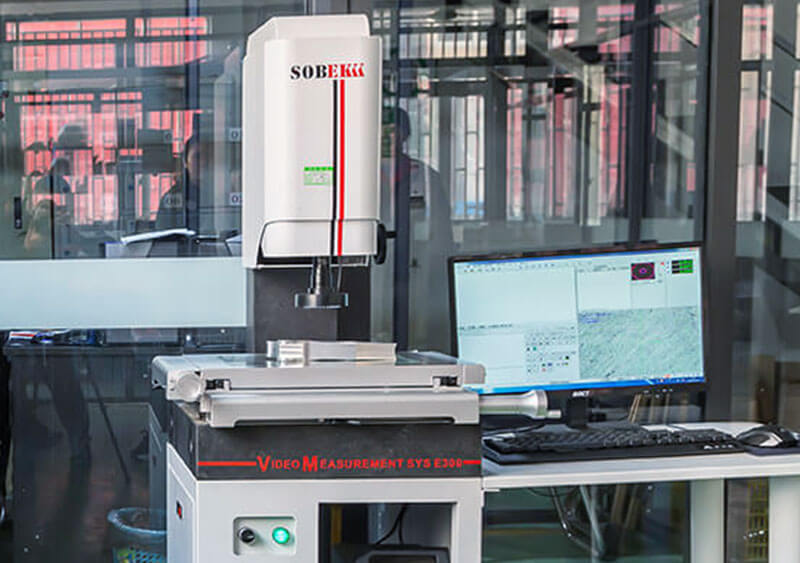

∎ Nleba anya n'ụdị na nyocha ziri ezi nke ihe nlele

Ndị otu nleba anya nke AISEN nwere, site na nnwale mbụ nke mkpuchi karama rọba ruo na nyocha nke nlele nnwale, ga-agarịrị nyocha akụkụ nke ukwuu na njikwa mma iji hụ na ihe ndị a na-emepụta nwere ike mechaa zute mmepụta ndị ahịa na ịkpụzi injection.Ihe niile achọrọ maka ịkpụzi.

∎ Ndị injinia nwere ahụmahụ dị afọ 20 na-eji sistemu jụrụ oyi mara mma na-emepụta eserese ziri ezi

■ Usoro nhazi nke ọma dị elu

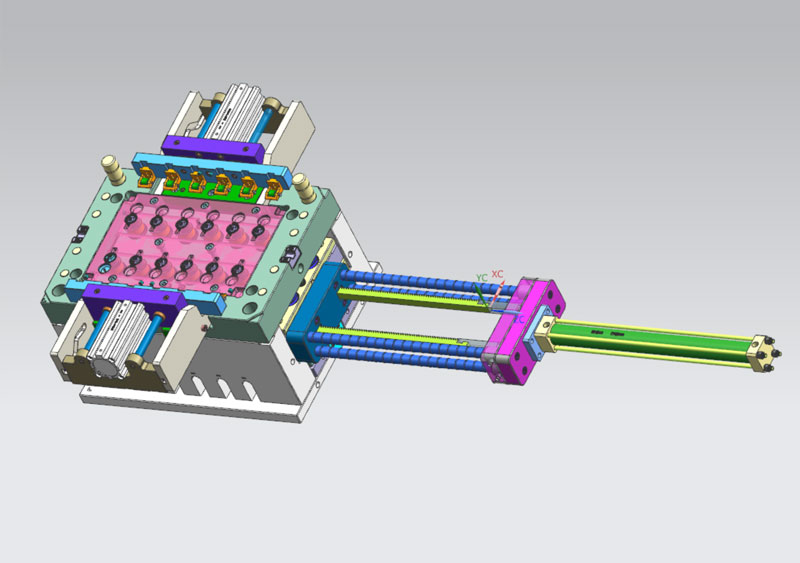

Otu ezigbo ihe mkpuchi karama rọba sitere na echiche dị mma nke ndị AISEN maka ịdị mma.

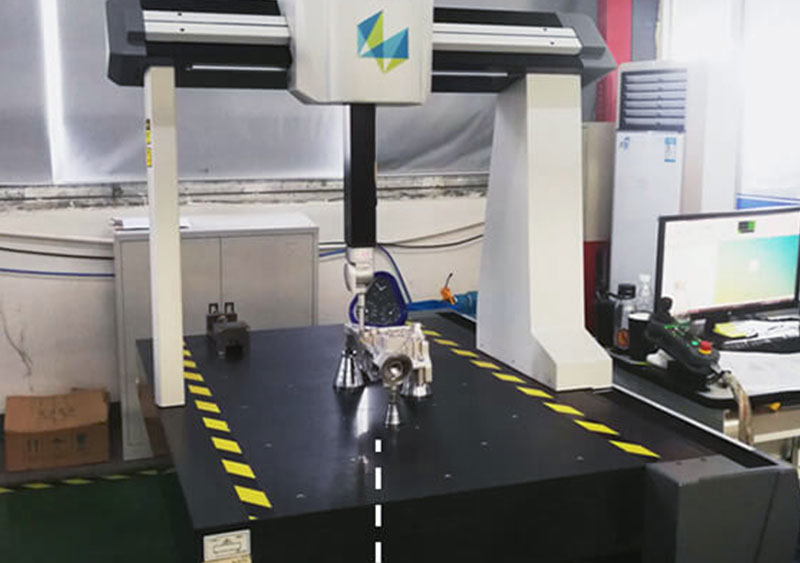

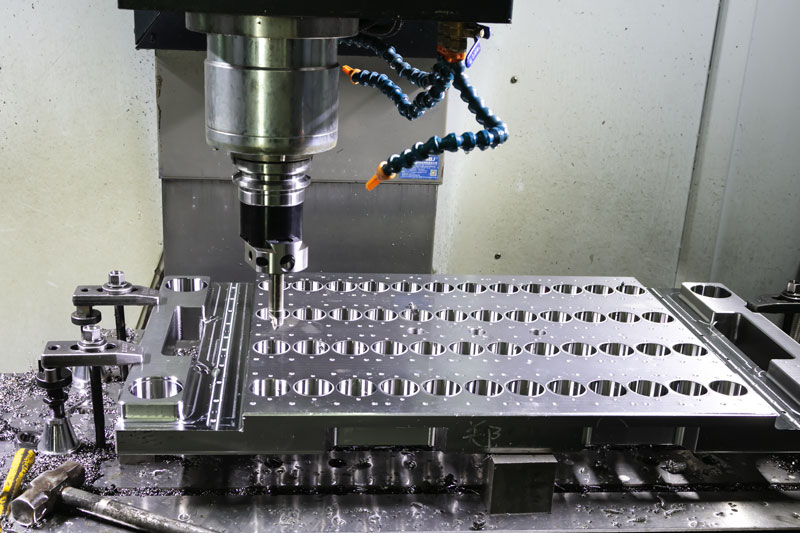

(1) Igwe CNC dị elu

Stable iji nweta "0.1μm ndepụta, 1μm ịkpụ, nm larịị elu roughness"

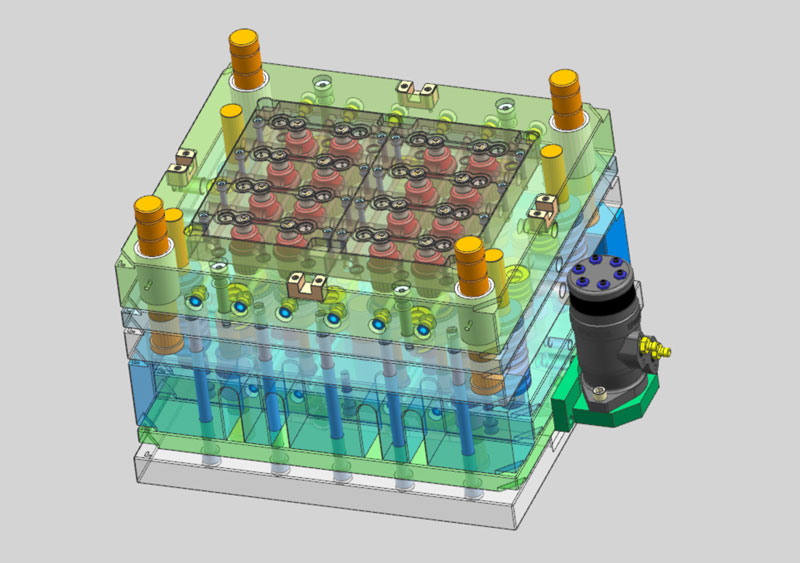

(2) Ọtụtụ ụlọ ọrụ CNC nwere njikọ atọ na axis anọ:

Stable iji hazie akụkụ ebu dị mgbagwoju anya, iji gboo ihe achọrọ nke nhazi ịkpụzi ziri ezi, nwere ike kwụsie ike iji nweta izi ezi machining 10-30μm.

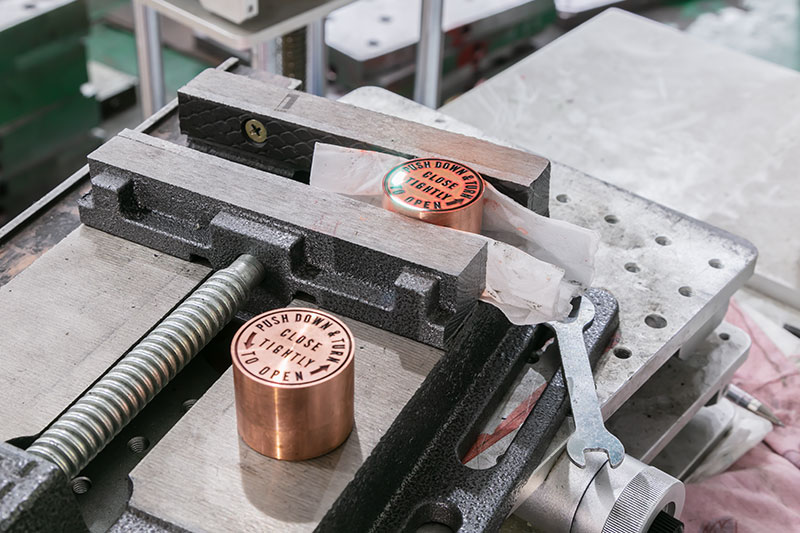

(3) Igwe ọkụ na-egbuke egbuke

Ọkachamara usoro, onwem na a dị ike nhazi teknụzụ nchekwa data, iji nweta elu ziri ezi (na-ekpeghachi n'ọnọdu izi ezi ≤2μm), elu arụmọrụ (≥500mm / min), kacha mma elu imecha (RA ≤0.1μm), zọpụta akwụkwọ ntuziaka polishing usoro, melite. elu nke ebu akụkụ

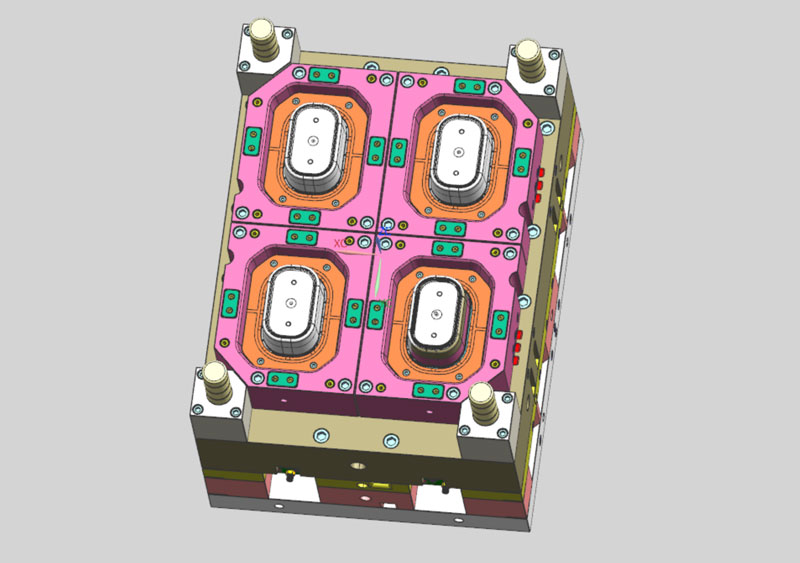

■ Usoro nhazi nke ọma dị elu

Ịhọrọ usoro onye na-agba ọsọ na-ekpo ọkụ na-ekpo ọkụ nwere ike hụ na ntinye ziri ezi na nke kwụsiri ike nke ọnụ ụzọ ámá niile nke ebu, ka o wee mepụta mkpuchi karama plastik ka mma.Na-ewere n'ime akaụntụ adaba nnọchi nke ebu-metụtara ngwa na mgbe e mesịrị oge, Anyị nwere ike inye dị iche iche ụdị nke na-ekpo ọkụ na-agba ọsọ maka ndị ahịa ịhọrọ.